Supergravity Fractionation Machines: Revolutionizing Solvent Separation

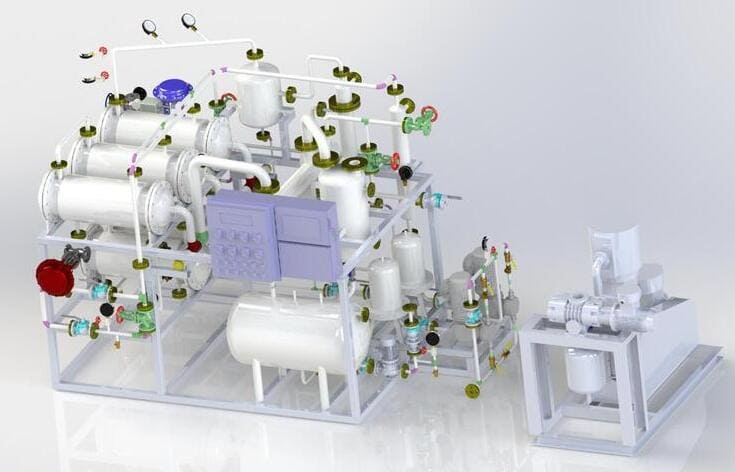

Supergravity distillation is a highly efficient technique for maximizing the effectiveness of distillation. Its wide range of applications in the petrochemical, pharmaceutical, biological and industrial sectors offers unparalleled advantages for the separation and purification of target substances.

Continuous or intermittent distillation recovery of organic solvents such as formaldehyde, toluene, methylal, ethylene glycol, acetonitrile, ethyl acetate, acetone, tetrahydrofuran, dimethyl sulfoxide, n-butanol, methylene chloride, silyl ether, cycloethane, isobutane, isopropanol, glacial acetic acid, acetic anhydride, DMF, DMSO, DMAA, DMDA, etc.

The Crucial Role of Hot Oil Transfer Pumps in Industrial Applications: Understanding Operations and Structures

Hot oil transfer pumps play a critical role in numerous industrial applications where the efficient movement of heat transfer fluids is essential. These pumps are specifically designed to handle high temperatures and ensure the safe and reliable circulation of hot oil within industrial systems.

In this article, we will explore the importance of selecting the proper structure for hot oil transfer pumps, delve into their operational principles, and highlight key considerations when choosing the right pump for specific industrial applications.

How To Make Molecular Sieve Membrane: A Complete Guide

Molecular sieve membranes are a new type of porous inorganic material developed in the last decade by cross-linking molecular sieve grains.

Did you know that a molecular sieve membrane can separate molecules based on their size and shape? It is based on the dual principle of preferential adsorption and molecular sieving. The separation is achieved by selective adsorption, depending on the size or polarity of the molecules of the mixed system, through molecules of similar size but different polarity.

Today, molecular sieve membranes are commonly used in membrane permeation evaporation liquid separation, membrane-catalyzed reactions, separation of aromatic isomers, alkanes, and olefins, meteorological separation, separation of biochemical products, and environmental protection.

Let’s learn how to make a molecular sieve membrane with our detailed guide!

Our guide includes step-by-step instructions for the preparation, coating, and characterization of molecular sieve membranes, as well as the effects of different synthesis conditions.

A Complete Guide: Membrane Separation Technology With Molecular Sieve Pervaporation Process

The principle of separation by PV process is to use the concentration difference or partial pressure difference of the components to be measured as the driving force for mass transfer, according to the dissolution performance of the raw material mixture in the membrane material, the diffusion rate and the difference in molecular size, so as to achieve the purpose of separating the components.

In this article, we will introduce the complete process and technology mainly about pervaporation membrane separation performance with inorganic molecular sieve membrane components.

Process Technology For Dehydration and Recovery of Ethyl Acetate

The increasing demand for ethyl acetate as an important raw material in various industries demands the need for advanced production processes and effective recovery and dehydration technologies.

The traditional production processes, although widely used, face challenges such as high energy consumption, low separation efficiency, and environmental pollution.

The pervaporation technique has emerged as a promising alternative due to its low energy consumption, no pollution, and good separation effect.

The optimization of the pervaporation process conditions can significantly improve its separation performance, making it a highly efficient and economic option for the recovery and dehydration of high-purity ethyl acetate on an industrial-scale production line.

The use of molecular sieve membranes in the pervaporation process has shown outstanding chemical stability and separation performance, making it a promising technology for the separation of ethyl acetate-water systems.

Methanol Recovery and Dehydration Process To Get 99.9%: A Complete Guide

Methanol is an important chemical with a wide range of applications. With the advantages of high temperature stability, low volatility and excellent clean energy properties, it is widely used in the production of chemicals, solvents, fuels and fungicides.

Effective recovery and purification of methanol is essential for many industries, including the chemical, pharmaceutical and energy sectors. By following the optimized process flow and using advanced process equipment and technology, you can ensure that you recover and purify methanol effectively and produce high quality anhydrous methanol suitable for your specific application.

Acetone Recovery and Purification Process for 99.99% Purity

While a large amount of industrial production and manufacturing of acetone wastewater makes great concern to the high disposal cost and environmental hazards, through the process of heating distillation, membrane filtration, fermentation method, isopropyl benzene oxidation synthesis method and other separation methods, pure acetone can be recovered and purified for reusing, the acetone recovery and purification process not only save a lot of procurement costs, but also reduce the pollution of the environment.

As a process equipment supplier on solvent recovery, I truely understand the importance of recovering and purifying acetone. In this post, I will list the main equipment and illustrate how to effectively recover acetone.

So it is significant to design proper process and equipment for acetone recover and purification, and reduce safety hazards associated with the accumulation of waste solvents.

Process Design and Control of 99.9% Isopropyl Alcohol

High-purity Isopropyl alcohol (abbreviated as IPA) of at least 99.5% is required to produce active pharmaceutical ingredients that meet regulatory standards, and any deviations from these standards can result in delays in the approval process.

Similarly, in petrochemicals and organic synthesis, the removal of water is critical to producing high-quality products and to ensure the safety of the process. So Isopropyl alcohol dehydration is necessary for process operations.

Ultimate Guidance of Screw Vacuum Pump

This instruction manual describes the operation and maintenance instructions and precautions for LG series, LGB series screw vacuum pumps. It is strongly recommended that personnel who operate or maintain the screw vacuum pumps shall read this manual carefully before operation and maintenance, in order to extend the service life of products.

Operation Guidance of ZJ/ZJP Series Roots Vacuum Pump

This series of Roots pump has a pair of synchronous high-speed rotors inside the pump, which achieve suction and discharge when the rotors are rotating. Since it works in the low pressure intensity range, the free path of gas molecules is larger and the resistance of gas leakage through tiny gaps is large, thus a high compression ratio can be obtained.

It can be used as a booster pump in series with the pre-stage pump, which can be used as a slide valve pump or rotary vane pump, water ring pump, oil ring pump and other vacuum pumps, but cannot directly discharge the gas into the atmosphere.

Wide range of applications: such as chemical medicine, food, electrical equipment manufacturing, vacuum metallurgical industry, vacuum degassing, vacuum melting, vacuum treatment of steel, and insensitive to small amounts of dust, high ultimate vacuum. when it is used in series with the former pump, the ultimate vacuum is between 0.0004 ~ 0.0001 Torr.