High Performance Liquid Chromatography

Multi Columns

EXdII BT4 & IP65

FDA CRF PAR11 Compliance

DQ/IQ/OQ/PQ Validation Document

CE Certificate Available

Special Patent Designed Column Distributor

- Complete Solution Specially Designed for Natural Product Purification.

- Design Based on SMB Technology.

- Running in Semi-Automatic or Full-Automatic Mode.

- Sample will Continuously Come to the Column and Pure Substance will Come Out of the Column.

Your Process is Guaranteed with Intensified Process Verification

Purity and concentration are indispensable indicators of active pharmaceutical ingredients (APIs). With the deepening of research, the requirements for high purity and content natural products are getting higher and higher, and how to improve the purity of products to adapt to the more demanding market requirements is what companies have to face.

Greatwall Process and Control(Wuxi) Co., Ltd. provides complete solutions of continuous high-performance liquid chromatography for customers, from the laboratory to the production process information-based process equipment to solve the purification and separation problem.

Product Portfolio

From Lab. scale to large industrial application turn-key solution.

- Analysis and Laboratory Preparation Scale HPLC

ARM CPU TCP/IP communication protocol

True color screen, Chinese/English interface

High cost performance, price is only 1/2 ~ 2/3 of imported products.

- Laboratory Preparation Chromatograph System

- Widely used in new drug R&D, biopharmaceutical and Chinese herbal medicine research.

- Maximizing cost-effectiveness and improving efficiency

- Small size preparative chromatograph separation system

- It is mainly used for drug fraction selection, clinical experiments of biological products, new drug performance research, and cost-effective drug ingredient production.

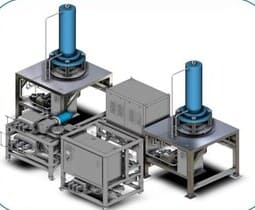

- Process scale High Performance Liquid Chromatography Separation System

- Purify drugs and biological products into pure ingredients

- The output is with a pure product volume of kg

- Preparative LC for natural product purification

- based on SMB technology

- born for large industrial production

- Optimized for dual or multi-columns chromatography

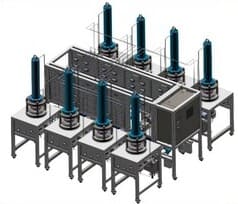

- Industrial preparative liquid chromatography for natural fraction purification

- specially designed based on SMB technology

- Continuous production facility with low solvent consumption

- high recovery and high purity of target product

What is Multi Stages High Performance Chromatography Columns

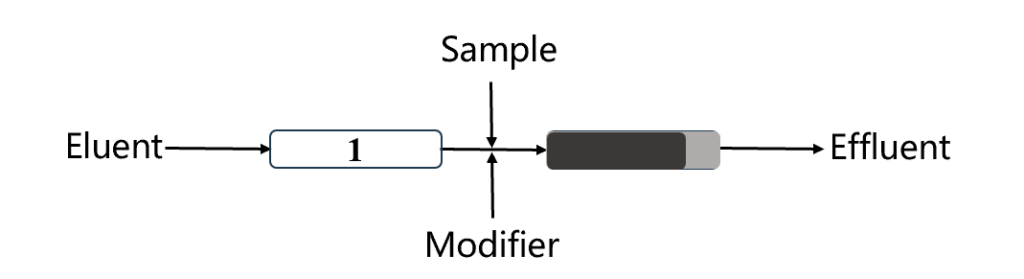

Separation Process of High-purity Target Components from Natural Products

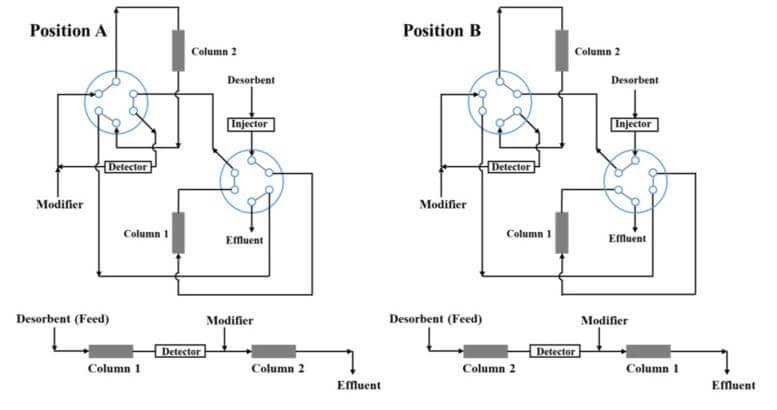

Eluent has low water content, and Sample and Modifier (which can be pure water) have high water content, so the upstream water content of the feed port is low and the elution ability is strong; while the downstream water content is high and the elution ability is weak.

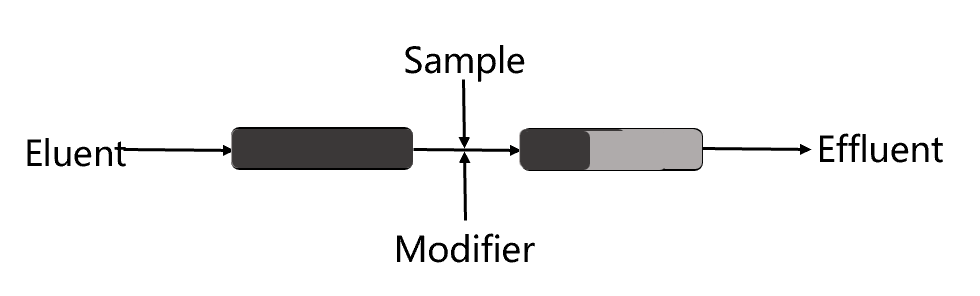

During the operation, the main component (gray in the figure) flows out, and when the rear miscellaneous (black in the figure) is about to flow out of the column 2, the system switches and the two columns exchange positions.

After switching, the Eluent with low water content eluted column 2, and the post-column was quickly eluted into column 1 downstream of the feed port.

At the same time, the water content in the column 1 is high, and the separated components move slowly, so that the main component can flow out of the column 1, and when the post-mix starts to flow out of the column 1, the system switches.

During the operation, the post-impurities does not flow out of the system, that is, it is captured in the system and is enriched.

Preparative HPLC Illustrating Diagram

Post-Impurities Capture Recycling Process of High Performance Liquid Chromatography System

Advantage ofMulti Stages Continuous Chromatography ColumnsComparing to Batch Chromatography

Multi Stages Continuous High Performance Chromatography Columns

Two fractions, no waste

Recovery up to 100%

High purity & high yield

Isocratic (step gradient possible)

Recycling is part of the process (up to 90%)

Solvent consumption is as low as 1/10th of the Unlimited number of fractions batch consumption

Product concentration comparable with input concentration (Feed)

Batch Chromatography Column

- Unlimited number of fractions

Recovery typically < 80%

EITHER high purity OR high yield

Isocratic or gradient

Recycling possible in isocratic mode

High solvent consumption

Strongly diluted product

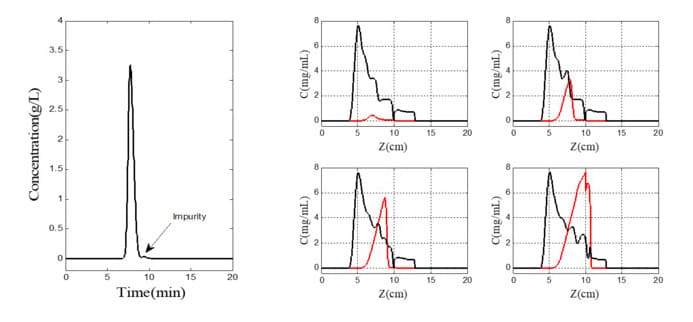

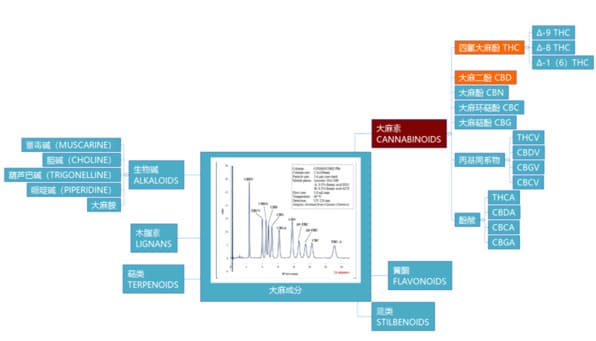

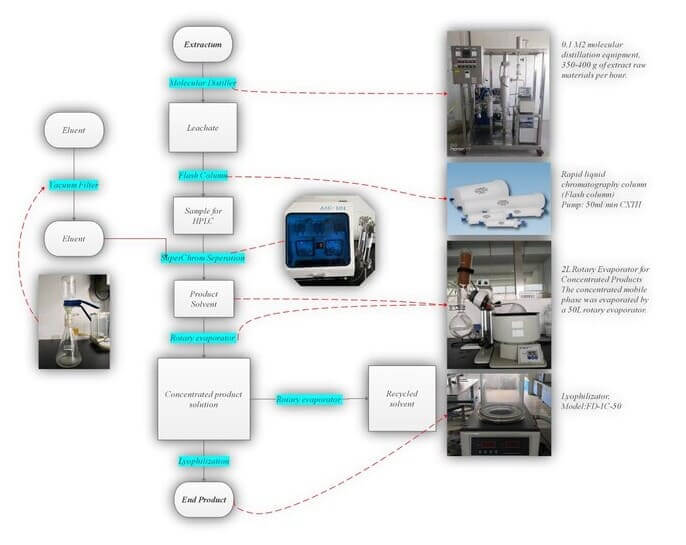

Extraction and Separation of Monomer CBD from Industrial Cannabis and Process to remove THC from Full Spectrum Oil

Mono CBD from Mixed Full Spectrum Oil

Removal of THC in full spectrum oil

CBD Lab. Process Instruments For research and process Scale up, whose capacity is approx. 100~150g

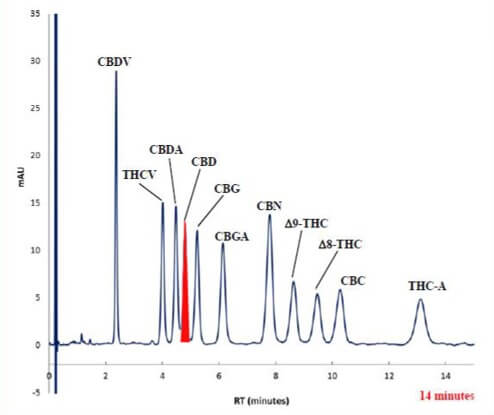

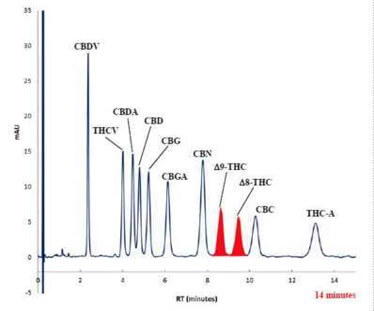

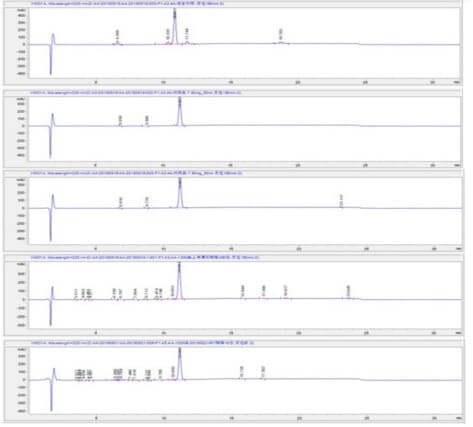

An Example of Removing THC from Full Spectrum Oil

- Purpose: To remove THC (The impurity behind the main peak)

Separation process Continue injection to improve production capacity and get a good target product

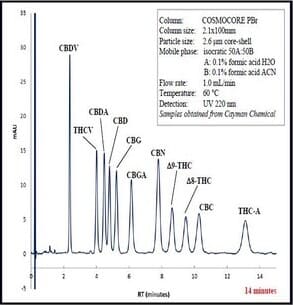

Analysis test and chromatography

HPLC: Agilent 1260

Column:4.6*150mm 5um,Welch-Ultimate-XB-C18

Column temprature:25℃

Flow rate:1mL/min

Wavelength:220nm, UV

Mobile phase and binary gradient:

Time min

Water %

Acetylene %

0

30

70

6

30

70

12

23

77

22

23

77

22.1

30

70

32

30

70

Practical User's Requirements

The daily processing of the mosaic leaves is not less than 1.5T;

It is required to meet the daily production capacity of CBD pure product of not less than 10kg;

The final CBD crystal is required to have a purity of ≥99.0%, wherein the THC does not exceed 0.1%;

The final full spectrum oil is required: CBD content ≥ 55.0%, THC content not more than 0.1%, total polyphenol content ≥ 80.0%;

It is required that the transfer rate of the CBD from the extraction of the leaves to the final product is ≥60% or higher, the higher the better;