Description

Fish lipids, in their crude oil form, exhibit various colors like yellow, brown, green, or black due to different pigments and particles. Oil refineries need to refine the crude oil to remove these colorants and enhance quality.

The decolorization process is specially designed to efficiently remove trace metals, free fatty acids(FFA), peroxides, residual saponification, phospholipids, and pigments in oil esters, including chlorophyll and other colored products from processing, decomposition, and oxidation.

Natural pigments can be effectively eliminated through thermal cleavage during deodorization process.

The goal is to improve refined oil color, obtaining a light or nearly colorless oil, rather than removing all pigments. It also removes various impurities, ensuring quality raw material for subsequent deodorization.

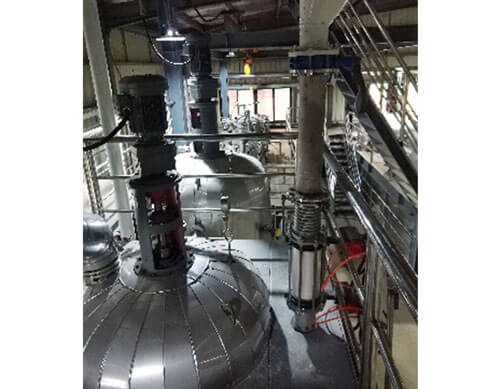

Decolorization is crucial, even for lightly colored crude oil, as it prevents flavor deterioration during complete refining. This process can be intermittent or continuous running, with the latter being more commonly used and energy-saving. The structure is divided into single-layer or multi-layer type, and the mixing mode is divided into mechanical mixing and steam mixing mode.

Our adsorption equipment offers automated control of the addition of adsorbent (white clay for example), ensuring precise and efficient decolorization.

It calculates the required amount based on output and adjustable addition ratios, adding white clay quantitatively to the negative-pressure decolorization tower or pre-mixing tank upon program initiation.

This proven system, utilized in numerous projects, has garnered user recognition. Additionally, it includes a reliable white clay air transport device, forming a well-established conveying and dosing system.

For more details of process flow and conditions, click here and discuss with us.

Revamp your decolorization process with our premium decolorization system. These process systems, available in both intermittent and continuous models, are engineered for optimal performance. You can choose from single-layer or multi-layer configurations, and our units feature efficient mechanical or steam stirring methods.

We take your specific oil type, quality requirements, and production capacity into account to provide tailored decolorization solutions. For larger capacities, consider our pre-decolorization tank to enhance decolorization results. Our track record speaks volumes—expect outstanding decolorization efficiency, minimal adsorbent usage, and low equipment operating costs. Elevate your oil and grease decolorization process with our top-tier decolorization towers.

Tailor Made Solution to meet your adsorption decolorization process requirements.

We pride ourselves on delivering high-quality, innovative solutions tailored to meet the specific process requirements of our customers.