Super Gravity Continuous Rectification Machine

Promising process intensification technology with enhanced transmission and heterogeneous reaction process by an order of magnitude higher than that in a conventional distillation column.

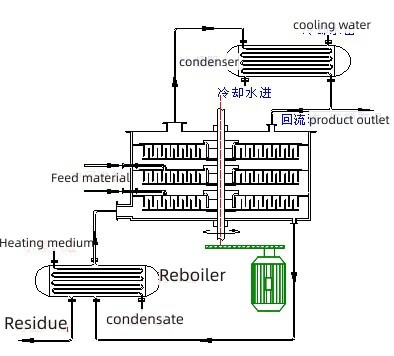

What is Super Gravity Rectification Machine

Supergravity distillation is a technique that utilizes an accelerating field to force the separation of a liquid mixture.

It uses the synergistic effect of a high-speed rotating vessel and a gravity field to produce a supergravity field that causes the liquid mixture to be subjected to a centrifugal force greater than 1G, thus achieving the separation of liquid mixtures.

The supergravity distillation equipment consists of a cylindrical vessel and two side inlets and outlets.

Inside the vessel, the liquid mixture is loaded. As the equipment rotates, the liquid mixture is subjected to a supergravity field and separated into different layers. These layers can be separated and collected through the side inlets and outlets.

Application Range of Super Gravity Fractionation

Petrochemical Industry:

Enables efficient separation of alkanes in crude oil, enhancing purity in the petrochemical sector.Pharmaceutical Industry:

Used for isolating active pharmaceutical ingredients (APIs) and purifying natural substances, such as essential oils and plant-derived active ingredients.Chemical Manufacturing:

Ideal for purifying specialty solvents, especially in complex chemical separation processes, fostering the production of high-purity materials.Environmental Remediation:

Facilitates the removal of contaminants from wastewater, particularly effective in ion exchange processes for water treatment.Biological Field:

Widely employed for the separation and purification of biological macromolecules like proteins, DNA, and RNA, offering efficiency in molecular research.

01/ Alcoholic water type

Methanol, ethanol, ethylene glycol, n-butanol, isobutanol, isopropanol, tert-butanol, etc.

- Initial concentration range:10%~80%

- Product concentration range:90%~99.9%

- Daily processing capacity range: 6~35ton/Day

- Application Reference

02/ Preparation of anhydrous ethanol/alcohol

- Initial concentration range:88%~92%

- Product concentration range:99%~99.5%

- Daily processing capacity range: 9~13.5ton/Day

03/ DMSO(DMF) water solution

- Initial concentration range:70%~90%

- Product concentration range:99.9%

- Daily processing capacity range: 6~30ton/Day

04/ Vapour extraction and desolventizing

- Initial concentration range:12%

- Product concentration range: less than 0.1%

- Daily processing capacity range: 20~30ton/Day

05/ Alcohol ester acid hydrocarbons

Ethyl acetate, methylene chloride, silyl ether, acetone, toluene, etc.

- Initial concentration range:20%~90%

- Product concentration range:92%~99.5%

- Daily processing capacity range: 2~30ton/Day

06/ Multi-component separation

Dichloromethane, tetrahydrofuran, cycloethane, isobutanol, etc.

- Initial concentration range:20%~80%

- Product concentration range:0~99.9%

- Daily processing capacity range: 5~15ton/Day

Advancements in Supergravity Fractionation:

Traditional distillation towers, be plate or packed, operate within the constraints of Earth’s gravity field (1 G) to facilitate heat and mass transfer between vapor and liquid phases, thereby effecting the separation of product components.

In contrast, supergravity distillation equipment represents a paradigm shift. It ingeniously transcends the limitations of conventional methods, where the liquid flood velocity restrains vapor phase velocity, hampering mass transfer enhancement. The groundbreaking supergravity technology propels separation efficiency to unprecedented heights, with the potential for over a 200-fold increase in specific applications.

01/Enhanced Separation Factor:

Traditional distillation relies on volatility differences among substances, often necessitating multi-stage processes for effective separation. Supergravity distillation uniquely expands the separation factor, significantly boosting efficiency, even in highly intricate separation scenarios.

02/Compact and Efficient Design:

The supergravity system accomplishes the same capacity with remarkably smaller equipment, reducing plant height by a factor of 8-10. This transformation results in a notable improvement in separation efficacy, a substantial increase in theoretical plates per unit volume, and a compact mass transfer unit height of approximately 1m.

03/Low-Cost Maintenance:

The streamlined design of the supergravity tower facilitates convenient and cost-effective maintenance. Unlike traditional packing towers that demand rigorous upkeep every six months, the supergravity tower merely requires a semi-annual machine seal ring replacement, reducing downtime and labor-intensive efforts.

04 Versatile Applicability:

Supergravity distillation equipment transcends conventional boundaries, catering to purification, extraction, adsorption, and various chemical reaction applications. Its adaptability positions it as a versatile solution across a spectrum of chemical processes.

Quality Guarantee

Services

24/7 Support

We are deeply engaged in research and technology development to provide detailed technical communication and consulting services, and to achieve timely response and feedback.

Specialized Solution

We will optimize the process application and engineering design based on your material profile and targeted application requirements

R&D Experimental Support

A variety of test equipment can support to carry out atmospheric pressure, reduced pressure, continuous, intermittent distillation experiments to verify and test process parameters.

Professional Production

Experienced manufacturing and inspection ensures that equipment manufacturing processes and structures meet production and quality requirements.

Installation and Commissioning Support

We provide the necessary operational training to the operators, in cooperation with the user to guide the start-up and commissioning of the equipment on site.

Zero Hesitation After Sales Service

Provide high quality and efficient after-sales service with zero hesitation.