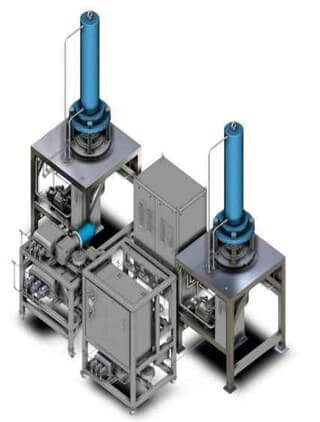

For large-scale commercial production line

In the last few years, the demand for medicinal Cannabidiol (CBD) in its pure, oil form without tetrahydrocannabinol (THC) has skyrocketed! And it’s only natural since the advancing legalization of the industrial Cannabis plant and the discovery of myriad benefits from this compound have made it the new sweetheart of pharmaceutical and herbal medicine entities worldwide.

But how is this natural, borderline miraculous substance processed and turned from hemp flower, leaves, and seeds into that oil millions around the world have been putting into therapeutic formulations and health benefit products? What sort of equipment is required for large-scale commercial production?

There are hundreds of process technologies to extract and isolate the CBD component, but the process to purify the monomer CBD component and remove needless THC from full spectrum oil is only a unique one, which is a highly technically demanding and precise task.

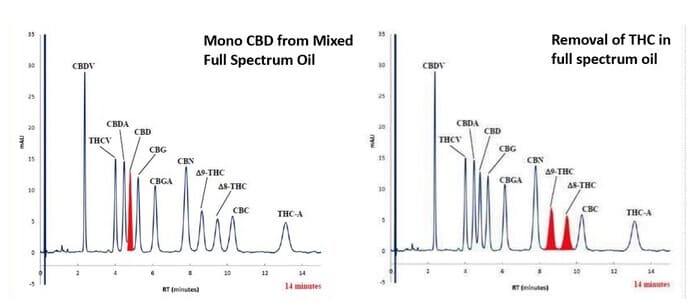

This article will present the most optimal and effective crude CBD oil extraction and purification process on commercial-scale industrial equipment and the High-Performance Liquid Chromatography (HPLC) for the removal of THC from full-spectrum oil.

The process of monomer CBD oil extraction and purification is intricate yet simple if we break it down into a few basic steps: Pretreatment of the Raw Materials, Drying & Crushing, Ethanol Extraction, Removing Impurities, Short-Path Molecular Distillation and Concentration, Solvent Recovery and Preparation, Separation and Purification with High-Performance Liquid Chromatograph, Crystallization, Drying, and Packing.

How CBD Oil is Purified in 8 Steps on Industrial Scale Equipment Units.

Let’s take a close look at a practical case project as an example for illustrating the fundamental process flows.

The process starts with the daily drying of hemp flowers and leaves of more than 1500kgs, and the complete process flow is designed to meet a daily production capacity of monomer CBD pure product of more than 10kg, it will definitely vary according to your raw material characteristic and active ingredients content.

From this processing line customer shall get the final full spectrum oil comprising greater than 55.0% CBD content, with less than 0.1% THC content, and total polyphenol content shall be ≥ 80.0%; It is completely specified that the transfer rate of the CBD from the extraction of the leaves to the final product is at least 60% or higher, surely the higher the better! Therefore, all of the following process equipment shall be properly selected to meet the target final CBD crystal to have a purity of higher than 99.0%, wherein the THC fraction does not exceed 0.1%.

1. Pretreatment of the Raw Materials: Drying and Crushing

Industrial cannabis leaves and flowers are the girl of the hour here. A non-psychoactive variety of Cannabis Sativa, it contains a variety of major and minor cannabinoids, like cannabidiol (CBD) in considerably lower quantities than the content we’re aiming at, and contains essentially no Tetrahydrocannabinol (THC).

Now, hemp is a particularly adaptable plant, being able to be planted in just about any climate and most soils. However, let’s say we want to produce around 10kg of CBD oil every day. In that case, we’d need at least 1.5 tons of hemp leaves and flowers!

First of all, we would need to dry it up so we’re able to crush it which we need as a base material for the entire process. For that, we use a Closed-loop dehumidification heat pump dryer! Apparatus is well known for switching up the open-loop evaporation method used for decades with a revolutionary, far more effective alternative. that will help us hit the ground running with the processing of the hemp plants. having the capacity of processing an astounding 25 tons of fresh leaves per day and get about 5 tons of dried herbal product.

After they’re all nice and dry It’s time we use the Multipurpose Crusher Model WN-600 to turn them into 5-10 mesh particulate matters, a process optimized to a clean industrial grade so we hit the ground running and get the most optimal dry particles. Remember that viscous materials or materials with more water should be sun-dried or heat pump machine dried to remove water and then crushed to achieve a better crushing effect. A dryer material with a water content of less than 5%-8% will be crushed with better performance.

With a capacity from 100 up to 700 kg of dried leaves crushed per hour we are again, comfortably above the 1.5 ton to 1.8 ton of raw material we need to process a day and well on our way to meeting the other requirements. Particularly because this machine keeps the waste of raw material to a minimum with its slick design, providing us with a solid foundation for an optimal system.

2. Ethanol Extraction

At this point what we want to do is run the product we got from the crusher to an extraction system that uses organic solvent as the medium for Intercellular molecular transfer and diffusion, so that extraction of active ingredients at the greatest extent from hemp plants.

No matter what substance you ultimately would like to obtain, the use of Ethanol as a solvent in CBD oil extraction is quite common and has an immense variety of benefits, as it is cost-effective and much more widely available and safe compared to other solvents. Not to mention the efficiency of the industrial process as a whole, able to have a material-to-liquid ratio of 1:5 (weight-to-volume ratio) and extraction rate of greater than 98% at working temperature below 40 degrees Celsius with the right equipment and configurations. Here the Countercurrent Flow Ultrasonic system is the right one, it’s a simple yet extremely methodical and optimized continuous extraction system made to overperform the required tasks. The outer layer of the immersion extraction tube jacket is provided with an insulating layer. The inverter takes 60 min at 30 Hz and is adjustable from 10-50 Hz with a total installing power of 41KW. The whole continuous extraction process is only about 60 minutes.

Why Use an Ultrasonic System?

The properly selected ultrasonic device can a certain extent enhance the herbal extraction efficiency. When the high-energy ultrasonic wave acts on the extraction medium, especially when the vibration is in sparse status, the medium is torn into many small cavities by the extraction equipment. And these small cavities are closed instantaneously. When closed, the instantaneous pressure of up to thousands of atmospheres is generated, that is a cavitation phenomenon. The strengthening effect of ultrasonic waves on the extraction and separation of various components is mainly due to their cavitation.

- The pressure generated by the bursting of tiny bubbles in cavitation makes the cell wall of the broken substance and the whole organism break in an instant, largely shortening the breaking time.

- At the same time, the vibration effect generated by ultrasonic waves strengthens the release, diffusion, and dissolution of intracellular substances, which can significantly improve the extraction efficiency.

- The ultrasonic crushing process is a physical process, there is no chemical reaction in the process, and the extracted bioactive substances remain unchanged.

- When cavitation occurs, a series of dynamic processes, such as oscillation, growth, contraction, and collapse, occur in the tiny bubble core in the liquid under the action of a high-intensity ultrasonic wave. Meanwhile, high temperature, high pressure, strong shock wave, and micro jet with a speed of more than 400km/h are generated around the cavitation bubble within a short time of the collapse. The peeling, denting, and comminution of solid surfaces create new active surfaces, and this interface effect will increase the mass transfer surface area.

- The turbulent effect produced during cavitation makes the boundary layer of mass transfer thinner, resulting in the concentration gradient reduction rate of solute in the interface layer being much higher than that of other methods.

- The perturbation effect produced by cavitation strengthens the micropore diffusion and eddy current diffusion in the solid-liquid mass transfer process, thus speeding up the extraction process.

- With the increase in ultrasonic frequency, the extraction time will be prolonged, and the accumulation effect of the ultrasonic field will result in an increase in extraction temperature.

- In the extraction process of natural products, cell wall breaking, solute diffusion, and equilibrium speed is related to unit area ultrasonic power, and all of them will affect the extraction efficiency and recovery, so generally, we use low-frequency and high-power ultrasonic device.

3. Winterization Process for Removing Chlorophyll and other impurities.

Now, before we get to the thick of it, we still need to concentrate the oil further for a more cost-effective separation and purification process, reducing the glycemic index and degreasing it so we have the cleanest possible product, including of course removing the chlorophyll to give the oil a more appealing look right off the bat.

To do this we use the disk centrifuge separator for low-temperature separation and multi-stage winterization tanks for degreasing and acquiring pure bioactive components from the extracts. After 8 hours of winterization process, the material is separated by centrifuge and further concentrated by a decarboxylated process kettle with the mild heating condition. This process line will need an industrial chiller for low-temperature crystallization conditions, high-purity nitrogen for protection, an industrial heating machine, and compressed air for working on diaphragm pumps.

4. Concentration with Short-Path Molecular Distillation

We’re in the thick of the matter from here! Using the exclusive automatic control continuous molecular distillation technology can effectively separate natural, complex compositions and small molecular weight differences of substances, a Liquid-Liquid Separation Technology especially applicable for heat-sensitive material separation.

The separation in Molecular Distillation System is realized by the average free path of the vapor molecules generally less than 25mm, which is greater than the distance between the evaporation surface and the condensation surface, when heavy and light molecular matter escapes from the liquid phase main matter, light molecular matter can reach inner condenser and get captured. While the heavy molecular matter has a shorter free path than the distance from the heating and condensing surface, it will not reach the inner condenser surface.

This process is high efficiency where we isolate the cannabinoids using their molecular weight traveling length difference under high vacuum conditions of 0.5Pa. We use specially designed thermal superconductivity technology to control the temperature difference within 0.5℃. The collected light phase components with high content CBD fraction will be transferred to the next process for further purification and separation operations.

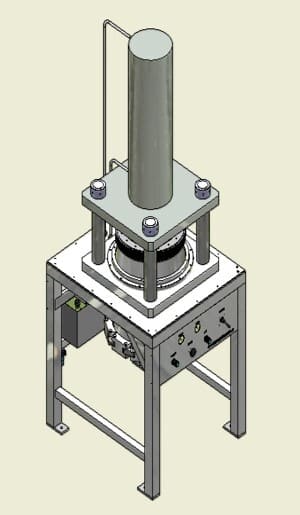

5. Coarse Separation with Dynamic Axial Compression HPLC

Pre-Column dynamic axial compression Separation System, with patented H-tree piston dispatcher and control panel that goes above and beyond to provide user customization that can account for a high number of variables. The column tube length is 650mm and the available bed length is 350mm. Being able to adjust air pressure as well as working pressure up to 20MPa and control valves and an emergency brake system, it’s ready for pretty much everything! The crude oil will undergo a process of decolorization and isolation to obtain and prepare pure and clean CBD oil components for a fine precise separation process.

6. Continuous Purification Process with High-Performance Liquid Chromatography

The star of the show! This is the most critical process of the entire purification line that requires precise design and calculation to meet the target performance. With directional development of the process route, which consists of the isolation of the THC and other components we would deem undesirable in a so-called pure high-content CBD oil.

This part of the process is preceded by continuously running the prepared crude oil through a multi-column liquid chromatography series for the isolation of different CBD content and other final products, such as 80%, 60%, 40%, and other full spectrum oil, and keep recovery rate over 97%, only need to slightly adjust the process parameters and remove nearly every trace of THC in the product leaving us with a full-spectrum CBD oil, a consumable that’s ideal for anyone who wants to enjoy all of the benefits the hemp plant has to offer without the psychotropic component THC brings to the table.

Furthermore, the process equipment used in this process route is also suitable for the production of other cannabinoid monomers. Such as CBDV, CBG, CBN, etc. We welcome your consultation and discussion with detailed process requirements.

Our work here is not done, however! In order to deliver the absolute purest form of CBD oil there is, we still need to take a couple of steps and get to work for that coveted ≥99% purity.

7. Crystallization and Freeze Drying

This is the process where we dissolve and precipitate the oil in preset temperature conditions in order to isolate solid material and leave almost as pure CBD component as it can possibly be. Continue with the Sublimation and drying process under vacuum conditions. It has no effect on the products’ chemical, physical properties, and activity of the product, cranking up the purity from around 70% to an incredible 90% and higher!

Here we make use of the Pilot10-15S Material Special Freeze Dryer because it completely freezes under vacuum, having no effect on the active components of the chemical, the moisture level is between 0.01% and 5% which is what we want (the less the better, since it will assure the material remains unchanged) and because it prevents the occurrence of agglomeration.

8. Concentration and Solvent Recovery

Throughout the whole process development, we always put solvent recovery and recycle utilization as the priority. In the main process of extraction, separation, and purification, only ethanol is used as a green organic solvent to facilitate the development of downstream products. The continuous and automatic operation of a large industrial processing line will significantly improve the efficiency and decrease the solvent volume, which is also easy to transform from pilot scale to industrial scale production.

we use a vacuum concentrator and continuous alcohol distillation tower with control systems in order to recover and prepare the required concentration of ethanol in the process line. The ethanol is evaporated and collected in storage tanks while the end product of pharmaceutical grade is ready to fulfill the immense demand it and its derivative products have been having in the market these days.

Conclusion

While the process design and operations can require a certain dexterity and an experienced laboratory team for process verifications, it can be simple once you know the most optimal process technologies and their basic steps, as well as what they consist of in general terms. You need a good pretreated material in the form of hemp flower or leaves, ethanol, and purified water for preparation, stable utility supply to run them through the equipment shown here in detail remembering what each does.

The evolution of the machinery and equipment used for the processing of CBD oil has seen a huge leap in a matter of only a few years. Not only that, the market and its sophistication are in the sweet spot where investing in the highest efficiency possible with equipment, to realize the informatization, intelligence, and integration of manufacturing and management promises to pay dividends for anyone in this business as the demand keeps rising even further.