Introduction

Tetrahydrofuran (THF) is a versatile solvent that finds its application in a wide range of industries such as pharmaceuticals, polymer production, and coatings. However, THF is hygroscopic and readily absorbs moisture from the atmosphere. The presence of water in THF can influence its reactivity, stability, and purity. This moisture absorption leads to a decrease in the quality and effectiveness of THF.

Therefore, it is necessary to carry out continuous dehydration of THF to ensure its efficient use in various applications. In this blog post, we will discuss the complete engineering and process flow for the continuous dehydration of THF and get high purity THF products, with moisture content below 100ppm.

The traditional method of drying THF involves the use of molecular sieves or other desiccants, which can be time-consuming, costly, and generate waste. A more efficient and sustainable approach is to use a solvent recovery system combined with a molecular sieve pervaporation membrane equipment.

What is the Feature of Tetrahydrofuran?

- Tetrahydrofuran (THF) is a cyclic ether with the chemical formula (CH2)4O. THF has a unique chemical structure that makes it a popular choice as a reaction medium in several chemical reactions. It is a colorless, water-miscible organic solvent with low viscosity at standard temperature and pressure.

- THF is a heterocyclic organic compound that belongs to the THF family. The heterocyclic nature of THF is due to the presence of the oxygen atom in its ring structure. The ring structure of THF makes it a cyclic ether. The presence of this ether functional group makes THF a suitable solvent for many organic compounds.

- The cyclic structure of THF makes it a unique solvent. The ring structure allows THF to dissolve both polar and nonpolar solutes. This property makes THF a versatile solvent that is used in a wide range of applications. For instance, in the pharmaceutical industry, THF is used to dissolve active ingredients and improve drug delivery. In the polymer industry, THF is used to dissolve polymers and improve their solubility.

- The boiling point of Tetrahydrofuran (THF) is approximately 66°C (150.8°F) at standard atmospheric pressure. However, the boiling point of THF can vary slightly depending on factors such as the purity of the solvent, altitude, and pressure.

Design Considerations and Equipment Selection

- The first step in designing a continuous dehydration process for anhydrous THF is to select the appropriate equipment. The choice of equipment depends on various factors such as the flow rate of THF, the desired purity of dehydration, and the degree of automation required.

- The most common equipment used for continuous dehydration of THF is a molecular sieve pervaporation membrane equipment. A molecular sieve inorganic membrane is a strong hydrophilic material that can selectively adsorb water molecules, allowing water molecular to pass through and purifying THF solution with moisture content less than 100ppm.

- We will select proper membrane areas to cover your desired treatment capacity and output purity. So multi stages of membrane components are integrated into the system for continuous dehydration process in series.

- Apart from the molecular sieve membrane components, the design of the process also involves the selection of appropriate pumps, valves, heat exchangers, and instrumentation. The pumps shall be capable of providing a constant flow rate of THF through pervaporation process. The valves shall be capable of controlling the flow rate and saturated vapor pressure. Heat exchangers are essential to maintain the desired temperature during pervaporation process, while instrumentation is necessary to monitor the process working condition and control the process variables such as pressure, temperature, flow rate, and vacuum degree.

- The complete engineering process design also request for sufficient utility supply of heating medium, cooling, chilling and vacuum conditons. These working conditions are key points to support the process operation and get target product. A stable utility supply is extremely important for equipment performance. Equipment and machinery rely on a consistent and reliable power supply to function optimally.

How Do You Dry Tetrahydrofuran?

Tetrahydrofuran (THF) can be dried using a variety of techniques, including distillation over sodium or lithium aluminum hydride, azeotropic distillation with a suitable solvent, and molecular sieves membrane.

It is important to note that the choice of drying technique depends on several factors, including the desired purity level, the amount of THF to be dried, and the availability and design of equipment.

In the case of continuous dehydration of THF, molecular sieve pervaporation membrane equipment is preferred due to its high efficiency and ease of operation. The process units offer several advantages over traditional drying methods, including higher purity, lower energy consumption, reduced waste, and increased productivity. It is a highly efficient and sustainable approach to obtaining high-purity anhydrous THF.

For example, it is a continuous process that can operate for extended periods without the need for frequent regeneration. Additionally, the equipment is easy to operate and maintain, and it does not require the use of hazardous chemicals or solvents.

The pervaporation membrane is a specialized membrane that selectively separates water molecules from THF based on their size and chemical properties. This process occurs through the application of a vacuum or low-pressure conditions, allowing the water molecules to pass through the membrane and leaving behind the anhydrous THF.

Process Flow

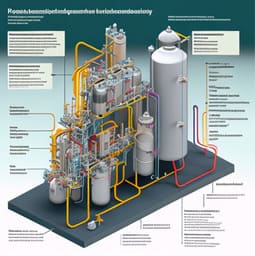

The process flow for continuous dehydration of THF (tetrahydrofuran) using a molecular sieve pervaporation membrane can be broken down into several steps:

- Pre-treatment of THF: The THF solution is passed through cartridge precision filters to remove any solid impurities that may block the molecular sieve membrane components.

- Evaporation: THF is fed into a preheater, where it is heated to a temperature of around 70-90°C to form a vapor for further process.

- Permeate: The vaporized THF is then fed into a molecular sieve pervaporation membrane unit, with flux ratio over 10000g/(㎡·h). This unit consists of a membrane module that contains a selective membrane tubes made from Na type zeolites, which allows the water to permeate through while retaining the THF.

- Dehydration: the THF permeate exits the membrane module and is collected as the product stream, while the water that permeates through the membrane is collected as the waste stream under vacuum condition.

- Condensing: The waste stream is sent to a condenser, where the water is condensed and collected as a liquid.

- Product Recovery: The dehydrated THF will be condensed by cooler and collected in a storage tank, ready for use in various applications.

Economic Benefits of Zeolite Pervaporation Dehydration

- Improved Product Yield: Molecular sieve pervaporation membranes can selectively remove water from reaction mixtures, allowing for better control over the reaction conditions and improving product yields. This can result in higher product purity, lower production costs, and increased profitability.

- Energy Savings: The use of molecular sieve pervaporation membranes can significantly reduce energy consumption compared to traditional separation techniques such as distillation. Energy saving by 50% to 75%. This can lead to lower operating costs and improved profitability.

- Reduced Capital Costs: Pervaporation membranes are relatively small in size and require minimal installation space, almost save 4/5 space and reduce infrastructure investment, which can result in reduced capital costs compared to larger, more complex separation equipment.

- Process Simplification: The complete system is automatically controlled that simplify industrial processes. This can result in shorter process times, lower labor costs, and increased efficiency.

- Environmental Benefits: The use of molecular sieve pervaporation membranes can lead to reduced environmental impact, as they require less energy and generate less waste compared to traditional separation techniques. Besides, it overcome azeotrope and avoid the third component recovery and pollution.

Project Reference for A 50,000 tons of Tetrahydrofuran Pervaporation Membrane Dehydration Equipment

Project Overview: The project involves the design, engineering, procurement, and construction of a pervaporation membrane dehydration unit for tetrahydrofuran (THF) with a capacity of 50,000 tons per year. The units utilize molecular sieve pervaporation membrane technology to selectively remove water from the THF stream and produce up to 99.8% THF, with moisture level lower than 0.2%.

Design and Engineering: The design of the pervaporation membrane dehydration unit is carried out based on a thorough analysis of the feed stream characteristics, including THF purity, water content, and flow rate. The unit system consist of a preheating system, molecular sieve membrane modules, condenser, vacuum pump, control system and water separation unit.

The engineering team works closely with the user to ensure that the unit is designed to meet their specific requirements.

Construction: The construction of the equipment is completed in the experienced factory with installation of the pervaporation membrane dehydration unit, including the preheating system, molecular sieve membrane module, condenser, and water separation unit. The construction team will work closely with the design and engineering teams to ensure that the unit is built to the required standards and is fully functional upon completion.

Commissioning and Start-up: Once the construction phase is complete, the unit will undergo rigorous testing and commissioning to ensure that it meets the required specifications. The start-up phase will involve the optimization of the unit to ensure maximum efficiency and performance.

Conclusion: The 50,000-ton THF pervaporation membrane dehydration equipment project has successfully provided a high-purity product with improved yield, reduced energy consumption, and lower environmental impact compared to traditional separation techniques. The total running cost of complete zeolite pervaporation membrane dehydration system is approximately US$25 per ton, which is much lower than US$90 on distillation columns system. The project will require close collaboration between the customer, design and engineering teams, procurement team, construction team, and operation parties to ensure successful project delivery.

Conclusion

In addition to being used as a solvent, THF is also used as a reaction medium in several chemical reactions. The presence of water in THF can affect the rate and yield of these reactions. Therefore, it is necessary to ensure the complete removal of water from THF during its production.

In conclusion, the continuous dehydration of THF is an essential process that ensures its efficient use in various applications. We are capable to provide complete system design, construction and supply for a continuous dehydration process to meet your process operation requirements.

If you have any questions about the continuous dehydration of tetrahydrofuran (THF), please feel free to contact us and discuss them with us.