Description

How to Produce Anhydrous Ethanol with A Minimum 99.5% Alcohol?

Basic Technical Introduction:

Using pervaporation, as a pivotal membrane separation technology, operates by selectively dissolving and adsorbing permeable components from the incoming liquid mixture as it moves upstream towards the membrane.

Subsequently, these components diffuse through the membrane under the influence of differential pressure across its surfaces. Once through the membrane, these components vaporize and are collected downstream, effectively achieving the desired separation outcome.

For more info, read here.

The Performance Of Zeolite Pervaporation Membrane Separation:

- Strong hydrophilic

- Separation factor:≥10000

- Flux:≥10000g/(㎡·h)

- Purity: > 99.99%

- Solvent resistance

- High-temperature resistance to 150℃

- Long service life: 4-6 years.

Features of Inorganic membrane module:

- Advanced membrane tube sealing technology

- Excellent membrane module design

- Graphite material is FDA-approved, resistant to organic solvent corrosion,

- High-temperature resistance, no aging, service life of more than 5 years

- Membrane module design: a combination of calculation, finite element analysis, and experiment.

- Membrane module with high-pressure resistance, long service life, and reasonable fluid structure.

How to Select A Proper Structure and Design:

1.Treatment capacity: 50ton/year~50000ton/year

2.Organic solvents such as alcohols, lipids, ketones, ethers, etc.

3.Raw material water content: 30%~1%

4.Outlet Product moisture content: 0.5%~0.01%

What is Our Customization Service and Solution:

We will formulate process solutions and services on customers’ production technology requests and practical demands, and manufacture the optimal facility.

1.Technical and process requirement communication

2.Lab. And pilot scale testing

3.Process flow design and modeling

4.Equipment selection and design discussion

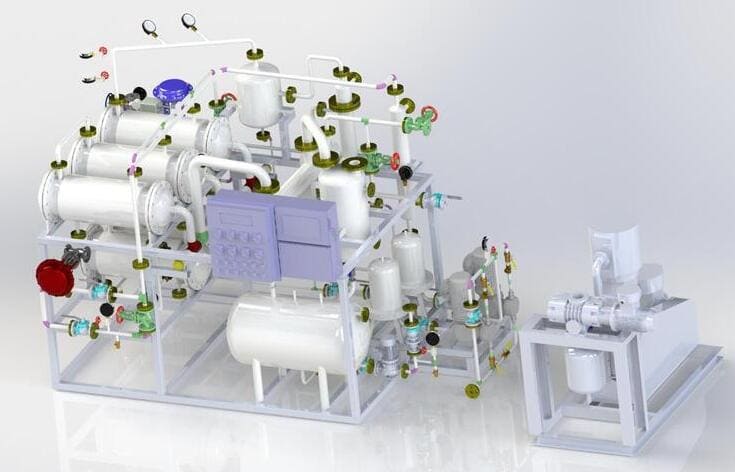

5.Equipment 3D design

6.Design process perfection and optimization

7.Manufacturing and quality control

8.Installation and commissioning

9.Inspection and delivery

10.After sales services