How Can You Improve the EPA/DHA Ratio in Your Fish Oil Concentration Process?

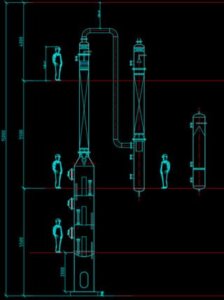

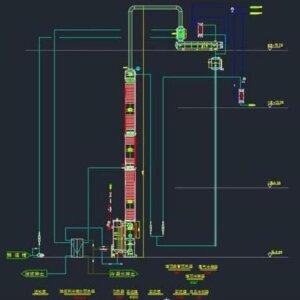

Short path distillation is a powerful technique used in the purification and concentration of fish oil fatty acids, particularly for increasing the EPA/DHA ratio.

This process allows for precise control over temperature and vacuum conditions, enabling the separation of different components based on their boiling points and molecular weights.

By fine-tuning these parameters, it’s possible to selectively concentrate EPA and DHA while minimizing the loss of other beneficial compounds.