Picture this: Your automated production line is humming along at 3 AM. Suddenly, a pressure spike fries a reactor. Downtime costs: 50,000/hour. Regulatory fines: 50,000/hour. Angry clients: Priceless.

Sounds like a nightmare? For many plants, it’s Tuesday.

Here’s the kicker: 63% of unplanned industrial shutdowns trace back to one overlooked component—control valves. These silent saboteurs dictate whether your process runs like a Swiss watch or a dumpster fire.

In industrial operations, control valves are the unsung heroes of process control systems. Acting as the “traffic cops” of fluid dynamics, they regulate flow rates, pressures, and temperatures to ensure seamless operations.

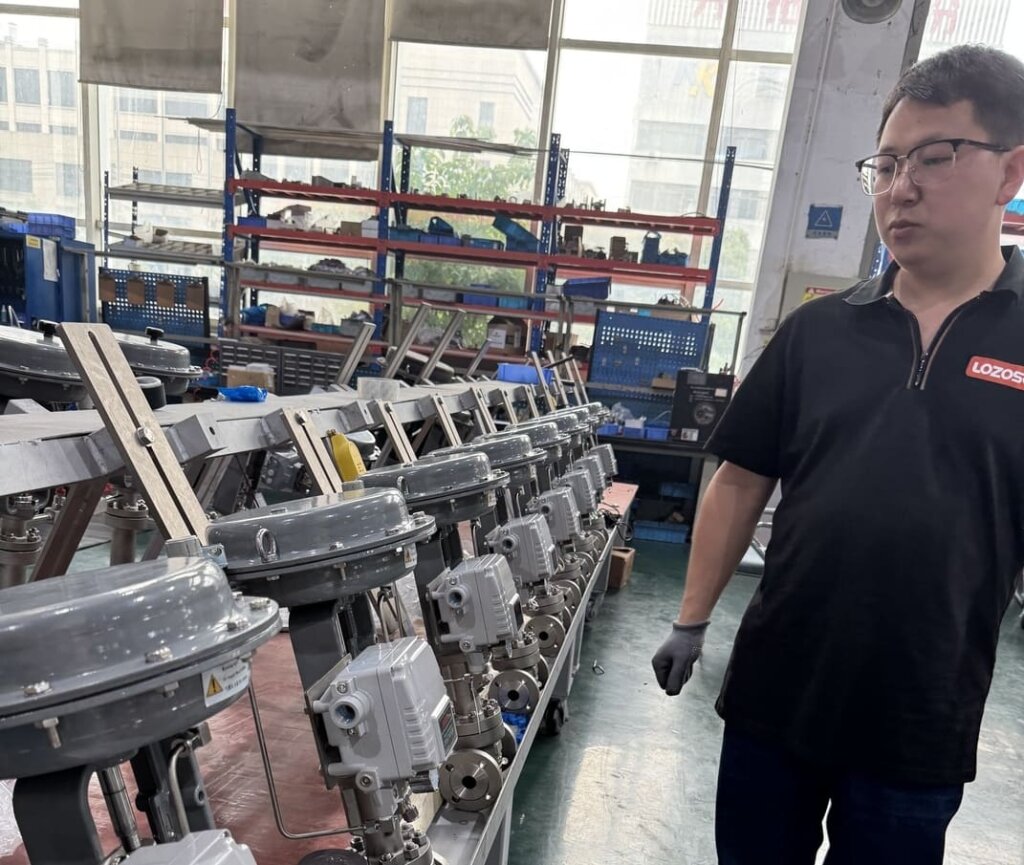

At Greatwall Process and Control, we’ve seen it all.

Last week, we inspected control valves for a client who’d lost $1.2M yearly to “mystery” energy waste. Spoiler: The culprit was a 3% opening degree drift in their control valves.

Let’s break down why your control valves might be costing you more than you think—and how to fix it.

The Vital Role of Control Valves

Control valves are pivotal in industries like oil and gas, power generation, chemical, and pharmaceuticals. They:

- Manage Flow: Adjust the volume of liquids, gases, or slurries in pipelines.

- Stabilize Pressure: Prevent system overloads or underperformance.

- Maintain Temperature: Ensure thermal consistency in processes like reactor cooling or steam generation. Without precise valve operation, systems risk inefficiency, safety hazards, or costly downtime.

The Science of Precision: How to Calculate and Select Control Valves for Flawless Operations

You’ve seen the horror stories—valves failing, batches ruined, regulators knocking. But here’s the truth: 90% of control valve disasters start at the design phase.

Think of your valve like a surgical tool. Would you let a surgeon operate with a rusty scalpel? Then why trust a generic valve to manage your high-stakes process?

Let’s break down the engineering rigor behind selecting valves that protect your bottom line:

The Design Philosophy: More Than Just a “Valve”

Control valves aren’t just on/off switches. They’re precision instruments engineered to:

- Regulate process parameters (pressure, temperature, flow)

- Safely shut off hazardous media (flammable gases, corrosive chemicals)

- Operate reliably under extreme conditions (cryogenic LNG, 500°C steam)

Key Selection Criteria:

- Pressure-Temperature Ratings

- Follow ASME B16.34 to calculate valve body thickness.

- Example: A 300 psi steam line needs a Class 300 valve body—not a “close enough” Class 150.

- Trim Materials

- Choose corrosion/wear-resistant materials (e.g., Hastelloy for sulfuric acid, Stellite for abrasive slurries).

- Cost of wrong choice: A 250k pump in 6 months.

- Leakage Class

- Use ANSI/FCI 70-2 standards:

- Soft Seals (VI class): Bubble-tight shutoff (0.00001% leakage) for toxic gases.

- Hard Seals: For high-temperature steam (but may allow 0.5% leakage).

- Use ANSI/FCI 70-2 standards:

- Actuator Sizing

- Calculate required thrust = (Valve seating force + Stem friction + Dynamic forces) x 1.25 safety factor.

- Mismatched actuators = valves that stick, chatter, or fail mid-cycle.

Step-by-Step: Configuring a Valve That Won’t Fail You

Let’s say you’re selecting a valve for a pharmaceutical reactor (sterile, 150 psi, 80°C, ethanol media):

- Pressure Rating: ASME B16.34 → Class 150 valve body.

- Trim Material: 316L stainless steel (ethanol-resistant, easy to sterilize).

- Leakage Class: VI class soft seal (zero ethanol vapor leakage = no explosion risk).

- Actuator: pheumatic diaphragm with 2,500 lb thrust (calculated via ISA 75.01).

What Happens If You Skip Steps?

A chemical plant ignored thrust calculations and paired a 10” valve with a weak actuator. Result: The valve jammed at 40% open during a pressure surge → $180k in damaged catalysts.

The Hidden Costs of Ignoring Control Valve Health

Most plants treat valves like plumbing fixtures: “If it ain’t leaking, don’t fix it.” But in automated lines, valves are the central nervous system.

Your Pain Points → Their Role:

- “Why does our energy bill keep spiking?” → Faulty valves force pumps/compressors to overwork. A 5% misalignment can spike energy use by 12%.

- “We keep failing emissions audits.” → Sluggish valves can’t regulate pressure fast enough, causing flare stack overloads.

- “Our product quality is inconsistent.” → A valve stuck at 70% open = uneven mixing ratios = rejected batches.

- “Maintenance costs are eating our budget.” → Undetected cavitation erodes valves 8x faster. Surprise replacements = $20k+

Industry-Specific Landmines (And How to Dodge Them)

- Oil & Gas: High-pressure methane needs ASME Class 600 valves + fire-safe design (API 607).

- Pharma: Electropolished trims to prevent bacterial growth (FDA cGMP).

- LNG: Cryogenic extended bonnets to keep seals above -162°C.

- Food: 3-A certified valves with crevice-free designs.

Need a Valve That Fits Like a Surgical Glove?

We’ll size, spec, and certify valves tailored to your process. Talk to our engineer by clicking here.

The Typical Technical Specifications Lists here:

| Nominal diameter DN | 25、32、40、50、65、80、100、150、200、250、300、350、400、500、600 |

| Pressure Rating | CL150、CL300、CL600、CL900、CL1500、CL2500 / PN16、PN25、PN40、PN63、PN100、PN160 |

| Leakage Class | Hard seal: Standard Ⅳ, optional Ⅴ, Ⅵ Soft seal: standard VI |

| Flow Characteristics | Equal percentage (EQ), linear (L) |

| Upper bonnet type | Standard, high-temperature, low-temperature, bellow-type |

| Flow to action | Single-seated valves: low inlet and high outlet (flow open) Cage valves: low inlet and high outlet (flow open) or high inlet and low outlet (flow closed) Pilot-operated sleeve valves: high in, low out (flow closed) |

| Valve Construction | Unbalanced single-seat, unbalanced cage, balanced cage; single-stage noise reduction, multi-stage noise reduction; Unbalanced multi-stage pressure-reducing, labyrinth multi-stage pressure-reducing |

| Actuator Configuration | Pneumatic diaphragm actuators, pneumatic piston actuators, electric actuators, etc. and handwheel devices |

How We Uncover Your Valve’s Secrets (Before They Cost You)

Here’s our battle-tested inspection playbook—designed to find what your team might miss:

1. The “No More Guesswork” Diagnostic

- Pain Point: “We don’t know WHY our line’s underperforming.”

- Our Fix: We use ultrasonic testing to catch internal leaks (even 0.5% seepage) and film analytics to predict wear patterns.

2. The “Regulatory Armor” Compliance Check

- Pain Point: “We’re tired of fines for pressure violations.”

- Our Fix: We validate valves against API 598/ISO 5208 standards and simulate worst-case scenarios (e.g., emergency shutoffs during peak load).

3. The “Zero Downtime” Calibration

- Pain Point: “Adjusting valves manually kills productivity.”

- Our Fix: We calibrate valves to respond within 0.1 seconds to control signals, with ±0.5% accuracy. Bonus: IoT-enabled valves self-report issues.

4. The “Sleep-at-Night” Certification

- Pain Point: “I’m always waiting for the next disaster.”

- Our Fix: Post-inspection, you get a digital health dashboard + a 12-month risk forecast.

Valve failures don’t send warning emails—they send invoices. Here’s how tiny flaws snowball into six-figure disasters (and how smart fixes turn them into wins):

Case 1: The $50 Gasket That Almost Sank a Chemical Plant

The Crisis:

A chemical plant’s main pipeline valve began leaking toxic vapor. Workers shrugged—“Just a minor drip.” Within days, the leak tripled. Safety alarms blared. Production halted.

The Fix:

Our experienced after-sales team diagnosed a rotted valve gasket (cost: $50) weakened by acidic media. But here’s the kicker: The leak had eroded adjacent pipe seals, risking a full blowout. We:

- Replaced the gasket with a Graphite metal-wound upgrade (chemical-resistant, 10x lifespan).

- Recalibrated the valve to prevent uneven seating.

- Trained staff on quarterly seal inspections.

The Cost of Ignoring It:

A 72-hour shutdown (220klost)+75k EPA fines + reputational carnage.

The Win: Fixed in 4 hours. Total cost: $3,800.

Case 2: The Steam Valve That Nearly Contaminated $1M in Pharma Batches

The Crisis:

A pharma plant’s steam valve refused to close. Sterilization cycles failed. Engineers blamed “software glitches” for weeks… while bacteria thrived.

The Fix:

Our experienced after sales engineer cracked open the actuator. Inside: gritty residue (from poor air supply) jamming the piston. But wait—the real issue? The valve was oversized, forcing the actuator to strain. We:

- Flushed the actuator with ultrasonic cleaning.

- Installed a 5-micron air filter ($10).

- Downsized the valve to reduce actuator workload.

The Cost of Ignoring It: Contaminated batches = $1M write-off.

The Win: 98% faster valve response. Zero downtime.

Why These Near-Misses Matter

Both cases started as “annoyances.” Both could’ve ended in catastrophe. The pattern? Reactive maintenance kills profits.

Your valves are talking.

- A slow-closing valve = “I’m clogged!”

- A weeping seal = “Replace me before Friday!”

How to Stop Losing Money (Yes, It’s Easier Than You Think)

Let’s be real: Your team is swamped. But ignoring valves is like ignoring a “check engine” light—it only gets worse.

Here’s Your Action Plan:

- Run a “Valve Health Snapshot” → Use our free sizing software to estimate your risk score in 2 minutes.

- Adopt Predictive Maintenance → Pair IoT sensors with our monitoring platform. Catch issues before they’re catastrophic.

- Partner with Valve Whisperers → Our engineers live for this stuff. We’ll handle inspections, so you can focus on production.

Your Valves Aren’t Just Parts—They’re Profit Guardians

In automated lines, control valves are the difference between:

- Flawless batches vs. scrap heaps

- 24/7 uptime vs. 3 AM panic calls

- Regulatory applause vs. six-figure fines

Ready to Turn Your Valves From Liability to Asset?

Book a Free Valve Audit Now→ Let our experts find hidden risks in 48 hours.

Resources: