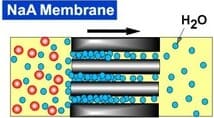

Permeation vaporization membrane separation technology is a process that separates or enriches a portion of an organic mixture by selectively absorbing and decomposing the components in the mixed solution. As the diffusion rate of each component in the membrane is different.

This technology is standing out due to achievable superior separation performance while most traditional methods of distillation, extraction, adsorption or other separation are difficult to accomplish.

It is featured with low energy consumption, especially suitable for near boiling point, constant boiling point mixtures and the same burst structure. It has many significant economic and technical advantages.

The pervaporation process involves many gradient changes, such as concentration, pressure and temperature, and there are many influencing factors mainly including the following:

- Membrane materials and structures as well as the physical and chemical properties of the separated components.

This is an important factor affecting the pervaporation process, which affects the solubility and diffusivity of the components in the membrane, and thus directly affects the separation effect of the membrane. In addition, the membrane material and structure also determine the stability, lifetime, chemical corrosion resistance and pollution resistance of the membrane, as well as the cost of the membrane. The molecular weight, chemical structure and steric structure of the separated component will directly affect its solubility and diffusion behavior, and the presence of concomitant effects between components will affect the subsequent separation effect.

- Temperature

In most cases, the separation coefficient decreases with increasing temperature, but there are some exceptions.

- The effect of liquid concentration

As the concentration of the preferred permeate component in the feed liquid increases, the total amount of permeate will also increase.

- The impact of upstream and downstream pressure

Permeation vaporization is not greatly influenced by the pressure on the upstream side, so the upstream side is usually maintained at a constant pressure. While the pressure change on the downstream side has a significant effect on the separation process. Generally, the permeability decreases as the downstream pressure increases. However, the separation coefficient increases at this time. Conversely, the separation coefficient decreases.

- Effect of film thickness

As the membrane thickness increases, the mass transfer resistance increases and the permeability decreases. The separation coefficient is independent of the membrane thickness because the separation effect is determined by the very thin active dense layer of the membrane.