When the stakes are high—tight specs, tight budgets, tight timelines—the smartest move is to test before you invest.

Uncertainties around feed quality, fouling risk, and real-world flux make budgeting risky and schedules fragile. The problem intensifies when each solvent behaves differently; the stakes rise, and so does the chance of rework.

Agitation: poor feed windows (pH, conductivity, chlorides), hidden impurities, and unclear energy demand can derail scale-up.

Solution: run a disciplined lab/pilot program that validates feasibility, quantifies performance, and de-risks scale-up—before you commit capital.

Our answer is a fast, data-driven sample testing service that verifies your feedstock, proves dehydration performance, and delivers a scale-up plan with membrane area, utilities, and OPEX estimates—so you can make a confident go/no-go decision.

Curious how your solvent will behave under temperature and vacuum, what pretreatment it needs, or whether 1,00 ppm (or lower) is truly achievable?

We turn a few liters of your sample into hard data: flux curves, selectivity, fouling tendencies, cleanability, and a credible path to production.

Who This Is For

Process engineers, plant managers, and procurement teams evaluating pervaporation dehydration for:

- Alcohols (ethanol, IPA, n-butanol), esters (ethyl acetate), ketones (MEK, acetone), ethers and glycols.

- Pharmaceutical, specialty chemical, flavors & fragrances, and renewable fuels applications.

- Green retrofits seeking energy cuts vs. conventional distillation.

Why Testing Matters

- Feed windows are unforgiving. pH, conductivity, chloride, and trace ions dictate membrane life and flux.

- Fouling is chemistry-specific. Dyes, salts, sugars, colloids, acids/bases—each demands a tailored pretreatment.

- Scale-up is earned. Bench data (flux, selectivity, vacuum/temperature, energy use) de-risks membrane area, utilities, and OPEX.

What We Test (Scope)

Feed Qualification

- Karl Fischer moisture (ppm to wt%), pH, conductivity, chloride (ppm), visual clarity/color.

- GC/GC-MS/HPLC for key organics and trace contaminants.

- Thermal stability checks (90–130 °C), “reacidification” behavior under heat/vacuum.

Pretreatment Assessment

- Clarification/filtration (µm cut selection), carbon or adsorbent trials, neutralization, demulsification.

- Rotary-evaporation and staged evaporation studies to remove light ends or inhibitors.

Bench Pervaporation Trials

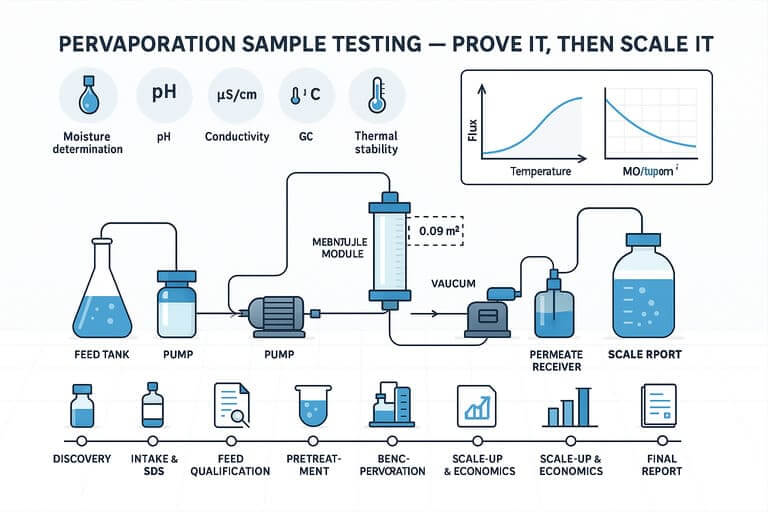

- Inorganic/hybrid membranes, effective test area 0.09 m² (or as specified).

- Controlled temperature and vacuum sweep; permeate condensation and mass balance.

- Flux (kg·m⁻²·h⁻¹), selectivity, moisture “approach to spec,” and fouling tendency over time.

Cleanability & Stability

- CIP chemistry screening (alkali/acids/solvent rinses), color stability of membrane tubes, cycle-to-cycle repeatability.

Key Points That Make or Break Performance

- Feed window: moisture ≤ 30 wt% for membrane longevity, pH 6.5–8.5, conductivity < 5 µS/cm, chloride < 20 ppm.

- Purity target: define moisture spec (e.g., ≤ 1000 ppm or sub-ppm) and any co-specs (acidity, ions, color).

- Thermal/vacuum regime: select T and absolute pressure to balance flux vs. solvent loss and heat duty.

- Membrane match: hydrophilic zeolite vs. hybrid options, chosen by solvent class and fouling risk.

- Pretreatment: keep particulates/colloids/dyes/salts/sugars out; protect membrane and condenser.

- CIP design: validated recipes that restore flux without attacking the membrane or elastomers.

- Heat integration: condenser/chiller pairing and sensible heat recovery to minimize kWh per kg water removed.

How the Program Works (Workflow & Deliverables)

- Discovery Call (30–45 min)

Process background, solvents, targets, plant constraints, and success criteria. - Sample Intake & Safety

We issue a Chain-of-Custody (CoC). You provide SDS, composition, hazards, and special handling notes. Typical volume: 5–10 L (larger upon request). - Feed Qualification Panel

KF moisture, pH, conductivity, chloride, clarity/color; GC/GC-MS/HPLC as required. You receive a quick-look memo within the first phase. - Pretreatment Screening

Filtration/adsorption/neutralization paths, plus heat/vacuum stability and reacidification checks. - Bench Pervaporation Runs

Stepwise temperature/vacuum matrix; continuous recirculation; timed sampling to your target spec. - CIP & Repeatability

Cleanability run(s) and flux recovery confirmation. - Scale-Up & Economics Pack(your biggest win)

- Membrane area and module count for your desired throughput.

- Utility loads (thermal oil/steam, chilled water, vacuum), mass & energy balance.

- Control philosophy outline and instrumentation shortlist.

- CAPEX/OPEX ranges and integration notes with existing unit ops.

- Final Report & Review

- Executable test summary with raw data tables and plots.

- Achieved moisture levels vs. spec, flux curves, selectivity, and fouling observations.

- Pretreatment and CIP SOPs (draft).

- Scale-up recommendations and next-step proposal.

What We Need From You (Checklist)

- Target specs (moisture ppm or wt%, co-specs such as acidity, ions, color).

- Current process data (feed composition, existing purification steps, operating T/P, pain points).

- SDS and known trace components (e.g., H₂S, acids/bases, salts, dyes).

- Preferred operating envelope (ambient vs. heated feed, allowable vacuum, materials constraints).

- Sample volume and delivery timing and packaging notes.

Optional Add-Ons

- Ion and corrosive species remediation plan (e.g., chloride reduction).

- Extended fouling studies (multi-day).

- On-site pilot skid rental and demonstration.

- QA documentation alignment (DQ/IQ/OQ/PQ templates) for regulated sites.

Typical Outcomes

- A clear go/no-go on pervaporation feasibility for your solvent.

- A validated pretreatment and CIP scheme that protects membranes and maximizes uptime.

- A data-backed scale-up with membrane area, utilities, and control logic defined—ready for budgeting and approval.

Quality & Confidentiality

- All work can be conducted under a mutual NDA.

- Samples are stored, handled, and disposed of per SDS and applicable regulations.

- Data, results, and reports remain your property.

Lead Time & Pricing

Project-dependent. We scope quickly after the discovery call and sample review.

You’ll receive a written quotation with milestones and deliverables.

Ready to Send a Sample?

Contact: Livia Zhou

Email: livia.zhou@greatwallcontrol.com

Subject line: “Sample Testing – [Solvent] – [Target Spec]”

Include in your email: your company name, contact details, solvent system, target moisture, required timeline, and any site constraints. We’ll reply with shipping instructions, CoC, and a draft test plan.