Description

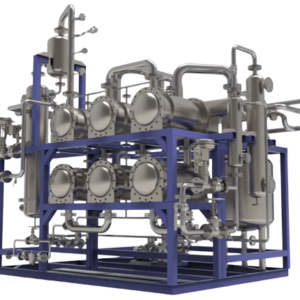

A Process Technology For Dehydration and Recovery of Ethyl Acetate

Crude Binary Ternary Product Separation Of Ethyl Acetate Using Pervaporation Technique

The increasing demand for ethyl acetate as an important raw material in various industries demands the need for advanced production processes and effective recovery and dehydration technologies.

The traditional production processes, although widely used, face challenges such as high energy consumption, low separation efficiency, and environmental pollution.

The pervaporation technique has emerged as a promising alternative due to its low energy consumption, no pollution, and good separation effect.

Explore more details here.