High Vacuum Distillation Unit And Application On Natural Product Development

High vacuum distillation is a process technology used to separate and purify substances with boiling points that are too high or too close together for traditional distillation methods.

This process involves applying a high vacuum to the distillation system, which lowers the boiling points for process operation and offers a more efficient and cost-effective method of separating and purifying substances.

The process is highly versatile and can be tailored to meet the specific needs of each industry. Additionally, the use of high vacuum distillation can lead to higher yields, greater purity, and a reduced environmental impact.

Across fish oil refining, high vacuum distillation maximizes yield of high-value Omega-3 ingredients, enabling nutraceutical, food and feed applications where purity, quality, and consistency are essential. Its mild conditions and precision make high vacuum indispensable for refining this delicate, in-demand material.

Molecular Distillation Systems for the Concentration of Omega-3 Fatty Acids

The molecular distillation process is highly efficient in removing impurities and producing high-quality omega-3 concentrates, but it requires specialized equipment and expertise. It is important to work with a reputable supplier who follows strict quality control measures to ensure the safety and purity of the final product.

the multi-stage molecular distillation process for fish oil concentration is an effective method for producing highly purified fish oil with minimal thermal degradation. The use of multiple stages allows for a high degree of separation and concentration of the desired molecules, resulting in a product that is suitable for a variety of applications, such as nutritional supplements and pharmaceuticals.

Complete Engineering and Process Flow for Continuous Dehydration of Tetrahydrofuran

Tetrahydrofuran (THF) is a versatile solvent that finds its application in a wide range of industries such as pharmaceuticals, polymer production, and coatings. However, THF is hygroscopic and readily absorbs moisture from the atmosphere. The presence of water in THF can influence its reactivity, stability, and purity. This moisture absorption leads to a decrease in the quality and effectiveness of THF.

Therefore, it is necessary to carry out continuous dehydration of THF to ensure its efficient use in various applications.

In this blog post, we will discuss the complete engineering and process flow for the continuous dehydration of THF and get high purity THF products.

Ultimate Guide to Import Chemical and Pharmaceutical Process Equipment from China

Overall, importing chemical and pharmaceutical equipment from China requires careful planning, due diligence, and attention to detail to ensure that the equipment is safe, reliable, and meets regulatory requirements. Working with a reputable supplier and logistics provider, and understanding the regulatory and customs requirements can help to ensure a smooth and successful import process.

Fish Oil Omega-3 Concentration And Refinement Process

The concentration and refinement process of fish oil ester has been applied to many fish species since 2000, and they are fundamental technologies to ensure high content and purity of Omega-3 ingredient production. This article will introduce highly efficient process technologies and equipment that have been used for Omega-3 concentration and refinement.

The concentration and refinement process for fish oil omega-3 involves several steps: Harvesting and Extraction, Refining Processes, Concentration.

Extraction and Separation of Monomer CBD from Industrial Cannabis & Process to Remove THC from Full Spectrum Oil

The process of monomer CBD oil extraction and purification is intricate yet simple if we break it down into a few basic steps: Pretreatment of the Raw Materials, Drying & Crushing, Ethanol Extraction, Removing Impurities, Short-Path Molecular Distillation and Concentration, Solvent Recovery and preparation, Separation and Purification with High-Performance Liquid Chromatograph, Crystallization, Drying, and Packing.

Solvent Recovery as Green Process Application

Solvent recovery is essential in achieving the goal of sustainable processing and green chemistry since the pharmaceutical industry uses solvents quite frequently. It is a method of recovering valuable materials from waste solvents or by-product extracted solutions during industrial process manufacturing.

The waste solvent treatment makes up one of the largest cost concerns in the chemical and pharmaceutical industries. Utilizing these recovered chemicals dramatically decrease the requirement for additional solvents, while also reducing the amount of waste produced. As a result, pollution and operational cost are minimized.

8 Steps for A Purification Process for Natural Ingredient-for Large Scale Industrial Production

A complete solution for purification and separation is required to further isolate and get high-quality, purified components, which meet the standard application in pharma, food nutrients, and cosmetic sectors.

The purification process of active pharmaceutical ingredients (APIs) is a complex and critical operation that requires a comprehensive solution. The rest of this article will take you to look into the 8 key typical steps that are particularly used for a complete purification process of natural ingredients on a large industrial production line.

Purification Solution for Highly Concentrated Omega-3 PUFA

This article presents a complete process guaranteed solution for purifying Omega-3 fatty acids to achieve a concentration above 97%, ensuring a high purity product for consumers.

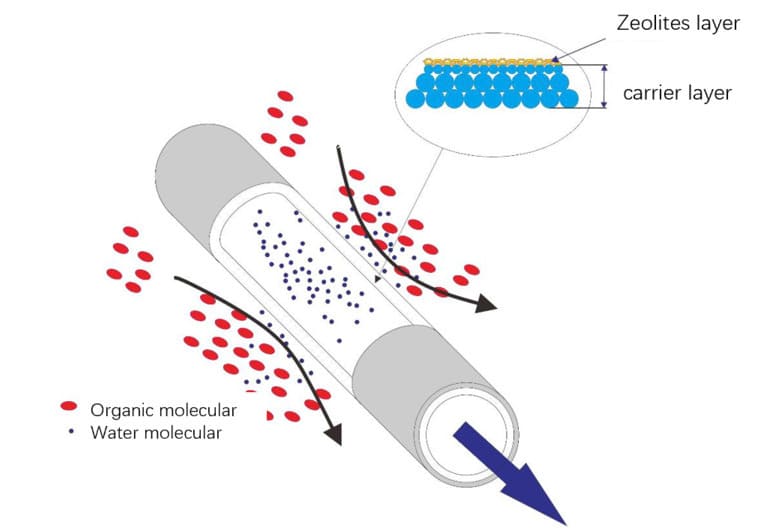

The Basic Condition for Pervaporation Membrane Separation

Pervaporation is a new technology of membrane separation and removal of water from industrial solvents.

Compared with distillation or rectification or other traditional separation technologies, pervaporation has outstanding advantages of high efficiency, low consumption, high recovery, convenient operation, safety, and environmental protection features, etc.