How to Select a Precise Solution for Short Path Distillation Unit for Fish Oil Concentration

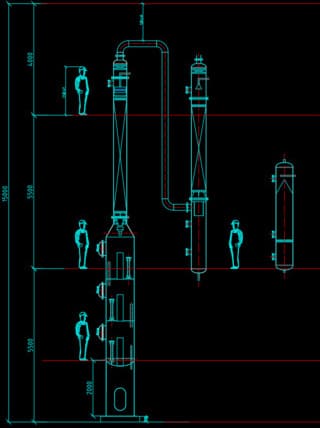

At the stage of fatty acid concentration process, the refined fish oil undergoes short path distillation, a process that operates under high vacuum and minimal heat to prevent oxidation and degradation of the Omega-3 fatty acids.

This technique is highly effective in separating and removing low molecular weight contaminants (e.g., PCBs, dioxins, plastisizers, and heavy metals) while concentrating the EPA and DHA content.

High-performance equipment will allow for fine-tuning these parameters to target the specific boiling points of POPs without degrading the quality of the Omega-3 fatty acids.

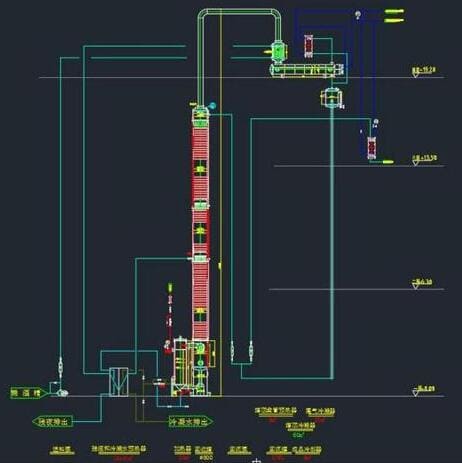

Advanced Physical Deodorization and Deacidification Process Equipment

The physical deodorization and deacidification process, equipped with advanced process equipment systems, stands at the forefront of this technological revolution.

This blog post explores how these advancements are setting new standards for industrial applications, offering insights for businesses looking to enhance their production capabilities.

The process conditions—temperature, time, pressure, and the ratio of steam to oil—are critically important for achieving the desired standard of oil quality and preserving its nutritional value.

Therefore, the design and process conditions of the deodorization tower can be continuously optimized to ensure that the generation of trans fatty acids is minimized, the removal of volatile pollutants is maximized, and valuable secondary components such as tocopherols and sterols can be controlled.

Optimizing Omega-3 Concentration in Fish Oil: Best Practices for Short Path Molecular Distillation

By controlling temperature, minimizing oxidation, and ensuring optimal equipment operation, producers can achieve a superior product that stands out in the market. Stay tuned to our blog for more insights into fish oil processing and the latest trends in the industry.

Modular Equipment: The Future of Process Engineering?

Modular equipment represents the cutting edge of industrial process solutions. It’s about bringing flexibility, efficiency, and innovation right to the heart of production lines. Think of it as building blocks for the industrial world, where each block is a self-contained, pre-fabricated unit that can be easily integrated into a larger system.

Modular equipment refers to machinery or systems designed in self-contained units or modules. These modules can be independently created and then integrated into larger systems. This design approach allows for flexibility in configuration, scalability, and often simplifies manufacturing, maintenance, and upgrading processes.

How to Guarantee Process Equipment Operation Target: 12 Steps for Peak Performance

Integrating the concepts of process improvement and efficiency enhancement in manufacturing into the blog post, we can focus on the significance of enhancing production quality, reducing manufacturing costs, and increasing production efficiency through technical innovation and process optimization. This will include adopting standardized processes, implementing automation, optimizing production workflows, and embracing continuous improvement. The importance of efficiency in reducing production costs, improving product quality, and enhancing competitiveness will also be highlighted. These concepts align well with the earlier focus on maintaining and optimizing process equipment, as they are integral to achieving overall operational excellence and sustainability in manufacturing.

How to Purify Ethanol: A Comprehensive Guide for Industrial Applications

In the realm of industrial and pharmaceutical production, the generation of significant amounts of organic waste, primarily composed of ethanol and water, poses environmental challenges. Conventional methods of treating ethanol waste, such as incineration, often prove inefficient, costly, and environmentally unfriendly.

As a leading supplier in process and control equipment, Greatwall Process and Control understands the critical importance of utilizing cutting-edge methods and equipment for purifying industrial ethanol.

This blog post will delve into the innovative technologies that are reshaping the ethanol purification landscape, providing invaluable insights for processing companies aiming to elevate their production processes.

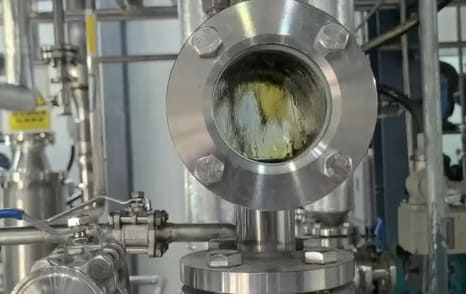

Unveiling the Magic of Short Path Molecular Distillation in Fish Oil Refining

Embarking on the journey of enhancing oil quality demands a technological marvel, and short path molecular distillation stands as the unsung hero in the fish oil refining process. In my realm as a seasoned sales specialist for short path molecular distillation equipment, I’ve witnessed the transformative power of this cutting-edge technology.

Unlocking the Secrets of Purity in Fish Oil: A Comprehensive Guide to Quality and Health Benefits

But not all fish oils are created equal. The magic lies in purity – with the highest-grade fish oils reaching a remarkable 96% purity level, offering medical-grade benefits.

Surprisingly, most products on the market fall short of this standard. Beyond heart and brain health, groundbreaking research in ‘JCI Insight’ by the University of Rochester reveals a specific fatty acid in fish oil can modulate immune B cell functions, potentially controlling inflammation and easing discomfort.

Omega-3 isn’t just a nutrient; it’s a powerhouse for overall wellness, even impacting allergy and asthma responses. Dive into the world of fish oil, where purity isn’t just a measure—it’s the key to unlocking its full health potential.”

This post is writen to unveil the purity of fish oil and its importance on to products quality and health benefits.

The Success Story of Molecular Distillation in Fish Oil Ester Concentration and Biodiesel Production

The state-of-the-art in concentrating Omega-3 fatty acids, a process pivotal in this evolution, shifted towards the fractionation of their ethyl or methyl esters. This method circumvents the high-temperature problem by employing multi-stage Short Path Distillation. This innovative approach has significantly improved the purity and concentration of Omega-3 fatty acids, with total EPA and DHA content achievable up to 70% or higher. Additionally, the variability of the EPA to DHA ratio can be finely tuned through control of distillation conditions and the degree of concentration.

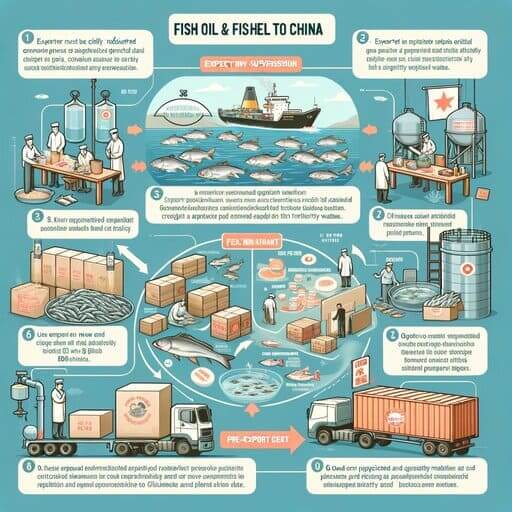

How to Navigate the Rising Tides of Exporting Marine Fish Oil to China?

China’s fish oil industry primarily relies on imports of crude fish oil and fish meal. According to the General Administration of Customs of China, in 2021, China imported 86,100 tons of fish oil products, approximately 33.5% increase year-on-year. Meanwhile, exports decreased by 16.91% to 22,600 tons. Given this trend and the escalating fish oil prices, it’s pivotal for exporters to understand the nuanced process of exporting marine fish oil and fish meal to China.