Our Services

We are committed to providing solutions that are environmentally friendly, energy-efficient, safe and effective. Our process solutions and services are specifically tailored to our customers' production technologies and practical requirements.

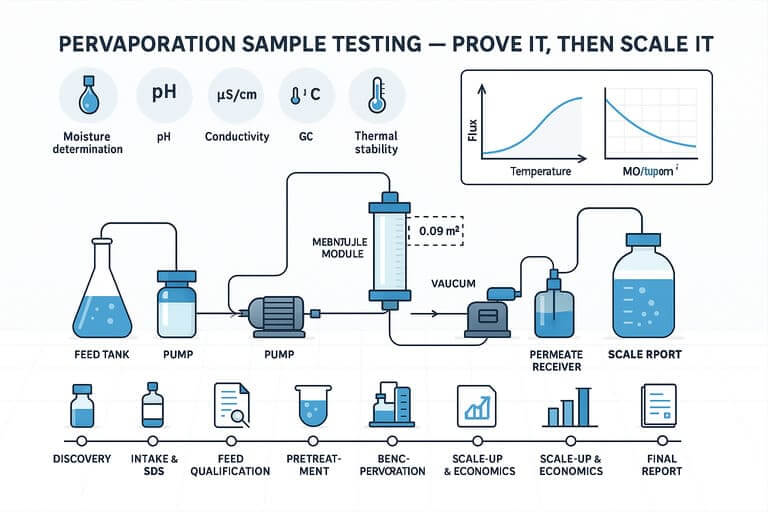

Lab.& Pilot Plant Testing

With a small number of samples, we will be able to perform laboratory and pilot scale testing and process determination to verify technology selection and optimize the final solution for targeted commercial production.

Customized Solutions and Services

We are proposing solutions based on your process production information and designing the process according to your actual working conditions. The optimized solution will be secured to save operation costs, increase the yield and save labor cost.

On-site Technical Support

Timely after-sales services are available online and on-site to support customer’s installation, commissioning, testing, and start-up operations. provide trainings on the equipment structure and process flow to operators for correct and professional operations.

Lab & Pilot Testing Service

Scale‑up & design verification for solvent dehydration and marine deep‑sea fish oil / Omega‑3 concentration

De‑risk your investment before you buy a full production line. Our lab and pilot programs generate hard data, confirm product specs, and translate results into a scoped process package for your site.

What we test

Solvent Dehydration & Recovery

Typical systems: pervaporation/zeolite membrane skids (hybrid with rectification), molecular sieves, and azeotrope‑breaking configurations for ethanol, IPA, acetone, THF, acetonitrile, Methanol, and related solvent blends.

- Typical objectives: 95–99.9% dryness(200ppm-minimal 100ppm); USP‑grade ethanol targets; energy and utility benchmarking; solvent loss minimization.

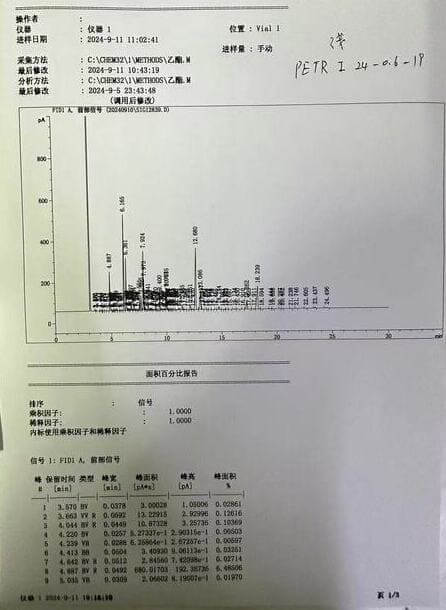

- Analytics: Karl Fischer, GC, density/RI, pH/conductivity, residue/impurity profile.

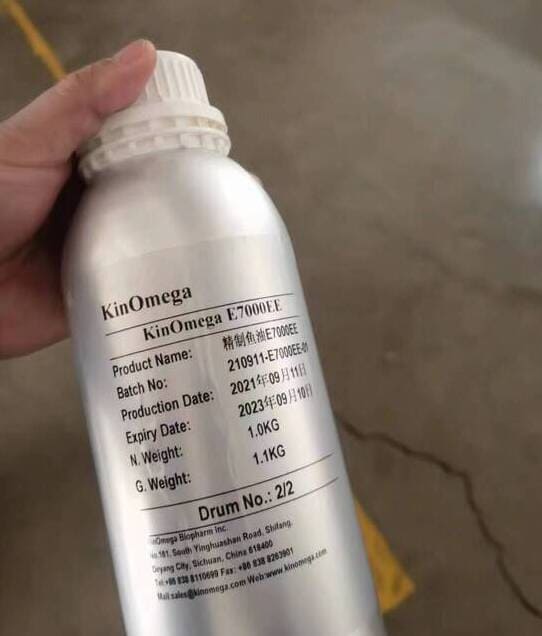

Integrated routes from crude oil to high‑purity concentrates. Modules include degumming/neutralization, bleaching, winterization, re‑esterification (TG↔EE↔rTG), short‑path molecular distillation (SPDU, multi‑stage), urea complexation, long‑path rectification/fractionation, micro‑deodorization, and HPCC finishing.

- Typical objectives: food‑ and nutraceutical‑grade 46/38 and 50:20; EE or TG ~70–90% concentrates; EPA‑ or DHA‑biased cuts; contaminant reduction within GOED/IFOS expectations; odor removal and oxidative stability improvement.

- Analytics: GC‑FID (FAME/EE), HPLC (distribution), peroxide/anisidine (TOTOX), residual solvents, contaminants (where requested), sensory panel.

- Origin/species (anchovy/sardine/algal), harvest/lot/date, antioxidant system.

- Initial metrics: PV, AV, TOTOX, FFA (% as oleic), moisture, metals (if available).

- Form: TG/EE/rTG; viscosity @ 25 °C; color/odor notes.

- Targets: grade (food/nutra/API‑adjacent), EPA/DHA targets (e.g., 50:20, 70%, 90%), odor threshold, contaminant goals (GOED/IFOS guidance), solvent residual limits.

- Sample quantity:

- Bench: 50–100g oil + process aids/solvents as applicable.

- Pilot: 10–150 kg typical (module‑dependent).

The Standard Workflow

Intake & NDA

We execute a mutual NDA and open a shared intake checklist.

Feasibility consultation

Define feed specs, target product, utilities, compliance boundaries (food/nutra/API‑adjacent), and any site constraints.

Sample & Data Package

You ship representative samples with required documentation. We verify identity, safety, and stability on receipt.

Bench‑Scale Screening

Rapid parameter sweeps to map feasibility, select operating windows, and estimate flux/yield/quality. Outputs: a shortlist of operating points for pilot runs.

Pilot Confirmation Runs

Run selected conditions on scalable rigs to confirm mass balance, energy draw, cut points, and stability. Capture steady‑state behavior and dynamic responses.

Design Verification (PDV) & Scale‑up Model

We correlate bench/pilot results with scale‑up models (e.g., LMH vs. activity for membranes; SPDU heat/mass transfer vs. residence time/vacuum; urea crystallization kinetics vs. cooling profile). We draft PFD, preliminary P&ID, equipment list, and utility summary.

Report & Proposal

You receive a formal data package with recommendations, risks, and an aligned estimate for your required throughput.

Manufacturing world-class equipment is only half the battle. Getting it to your facility, regardless of size or complexity, is where our service truly stands out.

Export Logistics & Project Delivery

Secure Global Delivery for High-Value Process Equipment

Our “Value Delivery” process includes a comprehensive Export Logistics Service designed to handle the most challenging shipments, including Out-of-Gauge (OOG) and heavy-lift cargo.

- Intelligent Stowage Planning: We analyze every dimension—such as the 11.7m length of pipeline skids or the 3.3m height of distillation columns to select the perfect container mix

- Heavy-Duty Seaworthy Packing: utilizing ISPM-15 compliant wooden cases reinforced for dynamic loads

- Risk Mitigation: Our team employs industrial-grade lashing, chocking, and center-of-gravity management to ensure zero movement during transit.

The Dedication Difference

We don’t just “ship” products; we engineer their journey. Our factory teams work with industrious precision to ensure that when your equipment arrives—whether it’s a single valve or a 23-package Short Path Distillation Unit —it is in the exact condition as when it left our floor.